The automobile industry is seeing an increase in the use of brushless alternators because they have many features in comparison to conventional brushed alternators.

A brushless alternator is an electrical device that produces electricity and energy using a spinning magnet. A housing with wire coils wrapped around it holds the magnet on a shaft that rotates inside of the housing. An electric current is induced in the field coil as a result of the magnetic field that the spinning magnet produces. A load, such as a lightbulb or a motor, is then connected to the current.

Continue reading the article to know more about brushless alternators, their design, and their operation.

The benefit of a brushless alternator

A brushless is more effective as the magnet in the traditional alternator is fixed to a revolving armature with brushes that make electrical contact with the field coil. The alternator may become less effective as a result of the brushes’ friction-causing wear and tear; this is the reason why BL alternators have no wear or friction.

Because of this, the brushless alternator operates more effectively and lasts longer.

By using a voltage regulator, it can convert more electrical energy into electricity than older alternators (which use carbon brushes), which means that less fuel is required to produce the same amount of power.

How does a brushless alternator operate?

The electromagnetic induction theory serves as the foundation for brushless alternators. An electric current is induced in a conductor when it is transported through a magnetic field, such as a copper wire. The length, high speed, and magnetic field intensity of the conductor are all factors that affect the strength of the current.

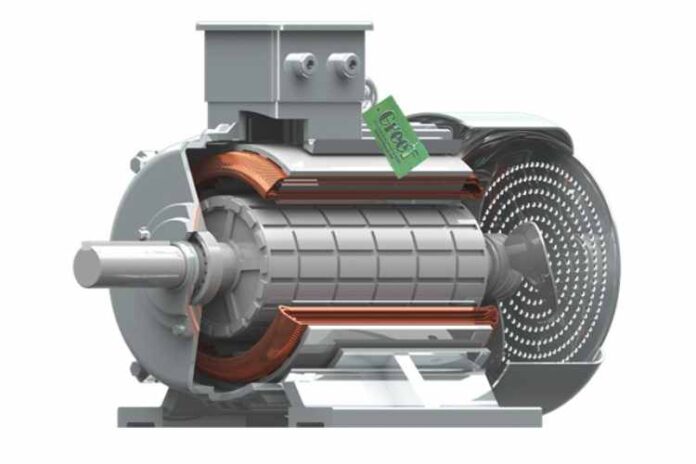

It is made up of a rotor, which rotates and houses the magnet, and a stationary stator which houses the field coil. The rotor is typically made of rare earth magnets or metals like neodymium or samarium, while the stator is typically built of steel or iron.

The magnetic field that the spinning rotor generates causes the stator’s field coil to conduct electricity as it spins. A magnetic field of its own is created by the induced current flowing through the wire coils, and it interacts with the magnetic field of the rotor. In response to this interaction, the stator rotates, the rotor spins, and a changing current (AC) is produced in the coil wire by the stator’s rotation.

After that, a load, like a lightbulb or a motor, receives the AC current that is running through the wire coils. To power electrical equipment, the load transforms AC current into DC current.

RELATED – HOW TO GET FREE DATA IN JIO: GET TO KNOW THE WAYS TO AVAIL THE BENEFITS OF FREE DATA

Construction of brushless alternators

The stator, rotor, exciter, rectifier, and BLDC controller are the main components making up a BL generator’s primary parts. The alternator’s stationary section, the stator, contains the windings, and the alternator’s rotating portion, which houses the magnets, has a rotor speed. The rotor’s field coils are powered by the exciter. The rectifier changes the alternating electrical current coming from the stator windings into direct current. To manage the output power voltage of the alternator, the controller modifies the excitation of the field coils.

The 3-phase alternator is the most typical kind of BL generator utilized in automotive applications. Three stator windings, each positioned 120 degrees apart, make up a three-phase alternator. Six magnets are positioned in two pairs of north and south poles on the rotor of a three-phase alternator. The exciter’s DC output excitation is applied to the rotor’s field coils.

The output voltage regulator of a BL generator is controlled by the field coils’ excitation. By intensifying the excitation of the field coils, the output voltage can be raised, however, lowering the excitation of the field coils will lower the output voltage.

BL Control System

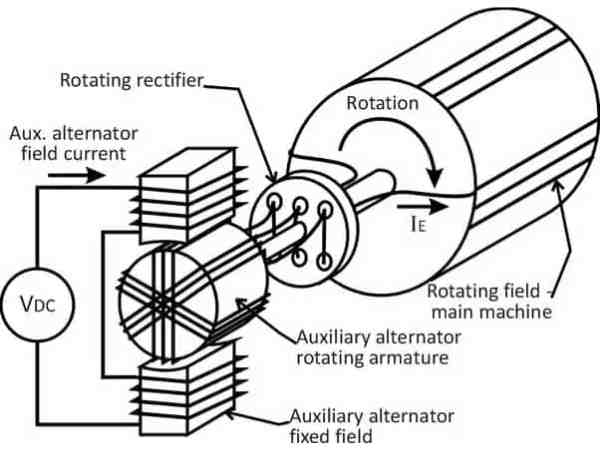

One of the main components, the exciter, is coupled to a large current source to saturate its stationary exciter field current to generate a strong magnetic field (350–400 gauss). However, The exciter’s output volume will be impacted by this. To produce a magnetic field, the output of the exciter is fed into the spinning field of the main alternator.

The amount of mechanical heat power produced by the main alternator depends on the strength of its magnetic field. The primary alternator’s output is subsequently affected, even though only a little amount of current passes through the exciter’s stationary exciter field coils but none of it must pass through brushes and slip-rings.

Components of the BL alternator

The stator and rotor are the two main parts of a brushless generator or alternator. The stator, which is composed of windings (coils) that produce a magnetic field in conjunction with a voltage regulator, is the stationary component of the alternator, and the alternator’s rotor, which rotates, is made up of magnets. To produce and conduct electricity, the rotor interacts with the magnetic field of the stator as it rotates to produce the necessary torque.

A brushless generator uses brushes to help move power from the rotor to the stator. The three rings’ slip, which are positioned on the rotor winding shaft and need additional torque, are connected to the stator’s windings. These rings come into touch with the brushes, which then deliver energy to them. These generate a magnetic field by allowing electricity to flow through the stator windings and conduct electricity.

Upkeep on BL alternators

There are a few things you can do to maintain the performance and extend the life of your BL alternator.

1. Regularly check the drive belt as it assists in rotating the alternator’s rotor, so maintaining it is crucial. Check for any wear and tear indicators, such as cracks or fraying.

2. Keep the alternator free of dirt because the interior components of the alternator can accumulate dust and dirt, which accelerates wear. To remove any buildup, use a soft cloth.

3. Examine the wiring as it may deteriorate over time or become slack. Keep an eye out for any wear or damage to the wiring.

4. Be mindful of your bearings. What makes the alternator rotate smoothly are its bearings. If they deteriorate, the alternator will have to work harder and this could reduce the alternator’s lifespan.

5. Ensure appropriate storage of the alternator. Keep the alternator somewhere cold and dry when it’s not in use. Rust and corrosion can be avoided in this way.

How does a BL alternator operate?

Rotor, Stator, and Rectifier are the components of a BL alternator. The stator, which is a coil of wire, houses the permanent magnet that makes up the rotor. Direct current (brushless DC motors) is produced when the rectifier transforms the alternating current (AC) produced by the rotor’s revolution.

A BL alternator’s key benefit is that it can produce electricity without using brushes to convert mechanical energy into current. As a result, the brushes do not deteriorate and need to be replaced regularly which saves on maintenance costs. Furthermore, brushless generators are capable of producing less electromagnetic interference (EMI) than brushed generators since they are more effective.

RELATED – TECHNOLOGY AND THE WAY WE TRAVEL TODAY

The Final Words

Though more expensive than brushed alternators, brushless generators or alternators are more effective. If you want an alternator that is both effective and reasonably priced, a BL alternator is the way to go.

We hope that you found this article helpful and now you know the working and application of Brushless Alternator.

Popular Search Terms

Email Hosting in 2022, 16 Inventory Management Tips You Need to Know, Atrix Keyboard Review, What Are the Great Benefits of Learning to Code?, 10 Ways to Make Money from Gaming, 5 Reasons Your Company Should Hire a DevOps Engineer, THE ULTIMATE ROCKET LEAGUE TRAINING GUIDE INCLUDING